Success in the market since 1928

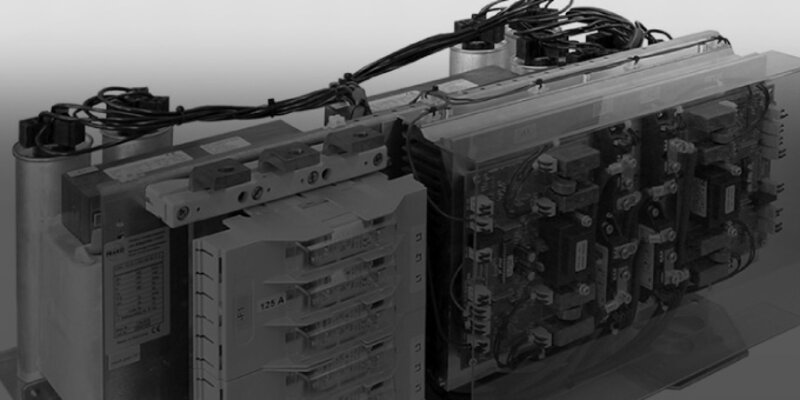

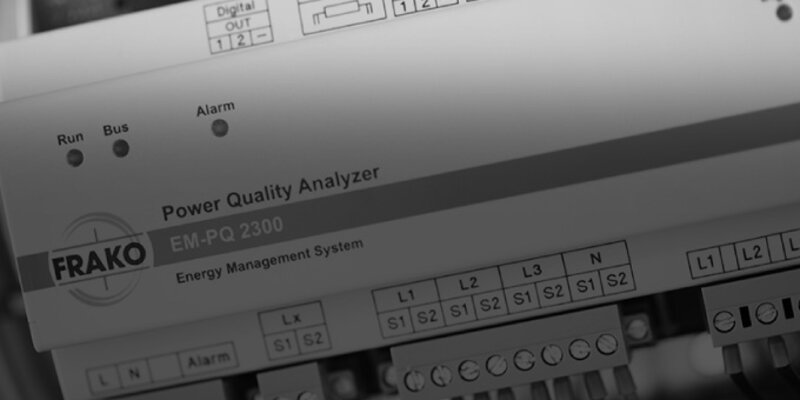

FRAKO is an internationally active company with the special strengths typical of an uncomplicated medium-sized enterprise: maximum quality, flexible manufacturing schedules, team spirit and a highly skilled workforce are what make us stand out.

With over 120 employees plus sales representatives in many countries, we work with great commitment to our customers. Developing practicable, safe and reliable products that are fit for the future is just as important to us as the dependable delivery of our systems to the specified installation site. At the present time, FRAKO systems all over the world are safeguarding the daily flow of energy. As FRAKO is also in demand as an OEM manufacturer, our products are also sold in many countries under the brand names of our partners — yet further evidence of our outstanding quality.

Some FRAKO facts and figures:

- Headquarters at Teningen, Germany

- Total site area 7237 m²

- Production and warehouse 5437 m²

- Sales, administration, research & development 1800 m²

- Since 2005 FRAKO has been a subsidiary of the industrial holding company AdCapital AG

- Code of Conduct on social responsibility of the electrical industry

Link: https://www.zvei.org/fileadmin/user_upload/Themen/Gesellschaft_Umwelt/ZVEI_Code_of_Conduct/pdf/ZVEI-Code-of-Conduct-Englisch-2014.pdf